Boost Converter Designer

This professional tool calculates parameters for DC-DC Boost Converters (Step-Up). It determines the minimum Inductance required for Continuous Conduction Mode (CCM) and sizing for output capacitors.

It includes a unique Component Sizing Guide that applies safety margins to help you select robust MOSFETs, Diodes, and Inductors for your SMPS design.

Specs & Margins

InputDerating / Safety

Parasitics

Design Analysis

CCM ModeCommon Boost Configurations

Standard voltage conversion scenarios and typical component requirements.

| Application | Input | Output | Duty Cycle | Switch Rating |

|---|---|---|---|---|

| Li-Ion to USB | 3.7 V | 5.0 V | ~26% | > 10V |

| 12V Bus to 24V | 12 V | 24 V | 50% | > 30V |

| Laptop Charger (Auto) | 12 V | 19 V | 37% | > 25V |

| LED Driver | 24 V | 48 V | 50% | > 60V |

Physics Explained

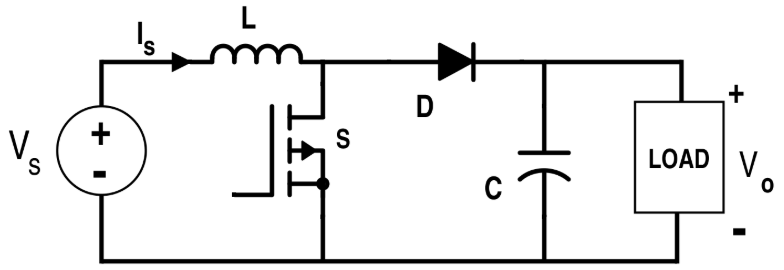

[Image of boost converter circuit diagram]Component Derating

Using components at 100% of their rating reduces lifespan. A 20-30% safety margin (Derating) is standard engineering practice for SMPS reliability.

RHP Zero

The Right-Half-Plane Zero (RHPZ) is a dynamic instability in boost converters. Your control loop bandwidth must be significantly lower than fRHPZ.

CCM vs DCM

CCM: Inductor current never hits zero (High power).

DCM: Inductor fully discharges every cycle (Low power/Light load).

How to Use

Set Operating Point

Define input/output voltages and load current. Ensure Vout > Vin. The tool assumes a standard non-isolated topology.

Set Safety Margins

Input your desired Voltage and Current margins (e.g., 25%). The Sizing Guide will automatically suggest minimum ratings.

Check Stability

Ensure your control loop crossover frequency is significantly lower than the calculated RHP Zero to prevent oscillation.